When it comes to plastic injection mold design, precision and efficiency are key. This is where CNC machining technology truly shines. With its ability to produce complex and intricate parts with unparalleled accuracy, CNC machining has revolutionized the field of plastic injection mold design. In this blog post, we will delve into the various aspects of CNC machining technology and how it is transforming the industry.

The Role of CNC Machining Technology in Plastic Injection Mold Design

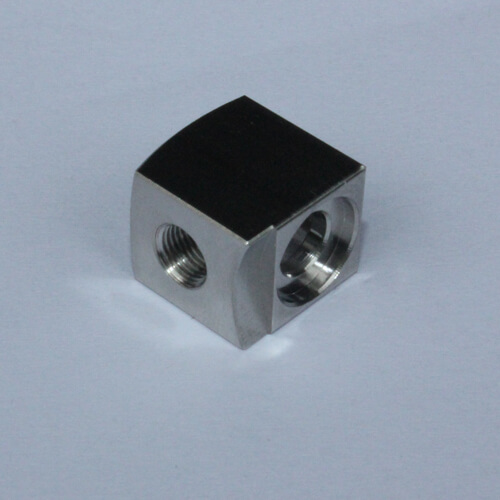

CNC machining technology has brought about a paradigm shift in the way plastic injection molds are designed and manufactured. By utilizing computer-controlled machinery, CNC machines can precisely cut, shape, and mold a wide range of materials with minimal human intervention. This level of accuracy and repeatability is crucial in the creation of intricate designs and fine details that can be challenging for traditional manufacturing techniques.

Precision and Accuracy: The Hallmarks of CNC Machining

One of the greatest advantages of CNC machining technology in plastic injection mold design is its ability to achieve remarkable precision and accuracy. The computer-controlled nature of the process ensures that each component is machined with consistent precision, eliminating human error and ensuring a perfect fit every time. This level of accuracy is especially crucial in industries where small deviations can result in product failure or compromised performance.

Efficiency and Time-saving Benefits

In addition to precision, CNC machining technology offers significant efficiency and time-saving benefits in plastic injection mold design. The automated nature of CNC machines allows for continuous and uninterrupted production, significantly reducing production time and increasing overall productivity. With the ability to operate 24/7, CNC machines enable manufacturers to meet tight deadlines and deliver high-quality products in a timely manner.

Versatility and Adaptability in Design

Another noteworthy aspect of CNC machining technology is its versatility and adaptability in design. With CNC machines, designers are not limited to traditional manufacturing constraints. The complex designs and intricate details that were once unachievable are now made possible through the capabilities of CNC machining. This opens up new avenues for innovation and creativity in plastic injection mold design, allowing for the production of unique and customized components.

SIBAI: Pioneering CNC Machining Technology in Plastic Injection Mold Design

When it comes to pushing the boundaries of CNC machining technology in plastic injection mold design, SIBAI is at the forefront. As a leading manufacturer specializing in CNC machining solutions, SIBAI is dedicated to delivering outstanding precision, efficiency, and quality in its products. By investing in cutting-edge machinery, highly skilled engineers, and a commitment to innovation, SIBAI continues to revolutionize the industry with its state-of-the-art CNC machining technology.

In conclusion, CNC machining technology has brought about significant advancements in plastic injection mold design. With its precision, accuracy, efficiency, and versatility, CNC machining has become an indispensable tool in the manufacturing industry. Whether it's creating complex designs or producing intricate components, CNC machining technology has paved the way for innovation in every detail. At SIBAI, we are proud to be pioneers in this field and will continue to push the boundaries of what is possible in plastic injection mold design.