Features of Sibai Machining Capabilities in Stepper Motor

Stepping motors are widely used in ATM machines, inkjet printers, cutting plotters, photo machines, spraying equipment, medical instruments and equipment, computer peripherals and mass storage equipment, precision instruments, industrial control systems, office automation, robots and other fields, especially suitable for applications requiring smooth operation, low noise, fast response, long service life and high output torque.

There are many structural forms and classification methods of stepping motors. Generally, they are divided into three types: reluctance motor, permanent magnet motor and mixed magnetic motor, according to the excitation method.

According to the winding on the stator, there are two-phase, three-phase and five-phase serie motors. The most popular is the two-phase hybrid stepping motor, which accounts for more than 97% of the market share. The basic step angle of this type of motor is 1.8°/step. When equipped with a half-step driver, the step angle is reduced to 0.9°. With a subdivision driver, the step angle can be subdivided up to 256 times (0.007°/micro step). Due to friction and manufacturing accuracy, the actual control accuracy is slightly lower. The same stepper motor can be equipped with different subdivided drivers to change the precision and effect.

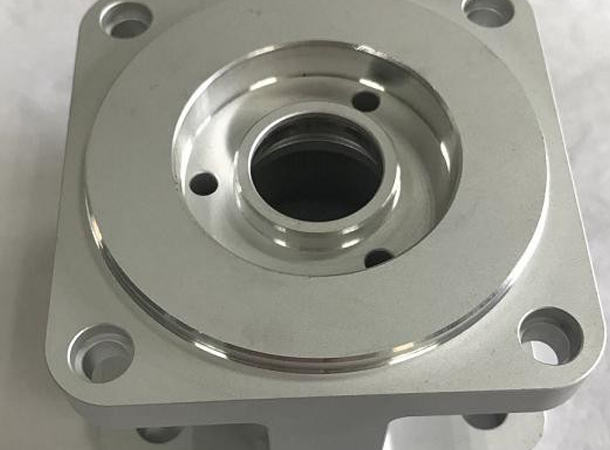

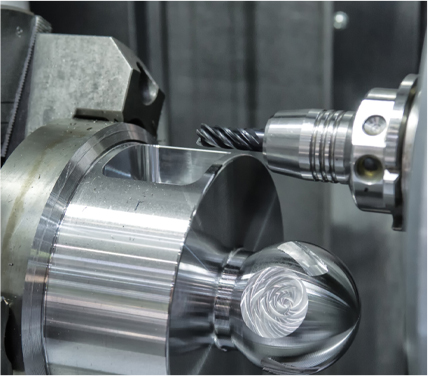

Sibai procudes the housings for stepper motors. After years experience, sibai now can provide the stepper motorr housings in large quantities in sured lead time

Welcome to Sibai.

We are looking forward to contact you!

If you have any questions or machining requests, please just leave your message here.