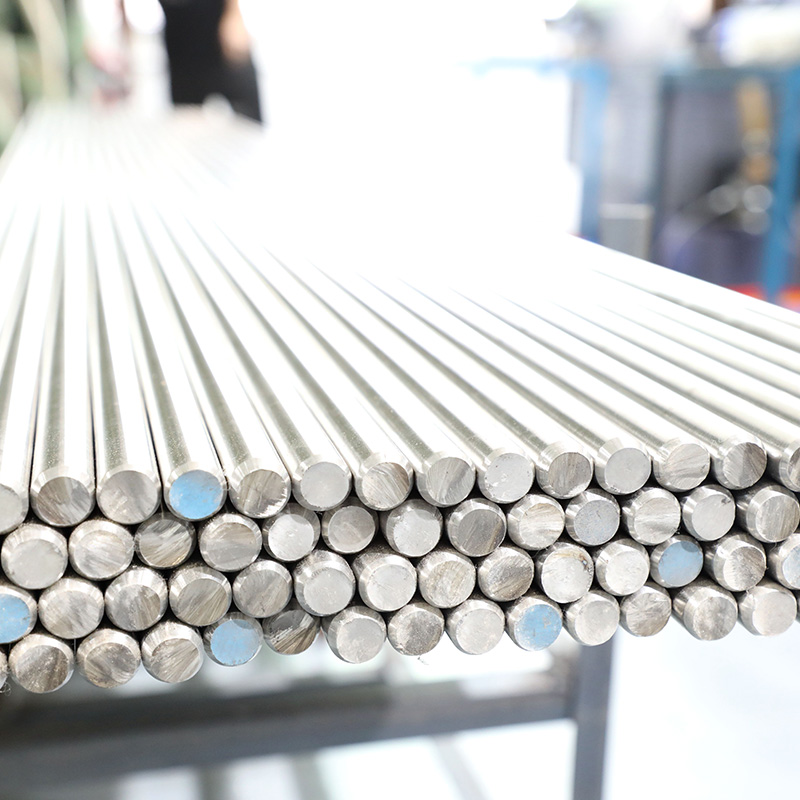

Stainless steel coils are widely used. The stainless steel coils are manufactured with different types of raw materials and advanced technology.

Sibai purchases a lot of stainless steel sheets and coils for laser cutting, stamping, bending and other processes.

Stainless steel coils are made by a variety of processes including cold rolling, hot rolling and extrusion. The thickness, diameter, length, and width depend on the process are determined by the processings.

Generally, the thickness below 3.0 is cold-rolled, and the thickness above 3.0 is cold-rolled and hot-rolled.

Cold rolled stainless steel coil thickness is generally in the range of 0.02mm-3.5m. Common widths are 5mm-1500mm.

Hot rolled stainless steel coil thickness is generally in the range of 3.0mm-14.00mm. Common widths are 1250mm, 1500mm, 1800mm, 2000mm.

Most of the stainless steel sheets purchased by Sibai are cut into slits, with specific width and length, according to the order requirements.

The main brands of stainless steel coils purchased by Sibai are: 430, 304, 2B/BA, 316L, 201, 430BA/2B, 410BA, 409BA/2B, 420J1, 420J2, 301, etc.

BA/2B refers to different surface treatment processes of cold rolling.

The 2B processing is cold rolling - annealing pickling - smoothing. While the BA processing is cold rolling - bright annealing - smoothing. The main difference is that the annealing process is different.

The 2B is annealing and pickling, and the surface is oxidized to a certain extent and darker.

The BA is bright annealing, the surface is not oxidized, and it is brighter.