Features of Sibai Machining Capabilities in Sanitary Ware

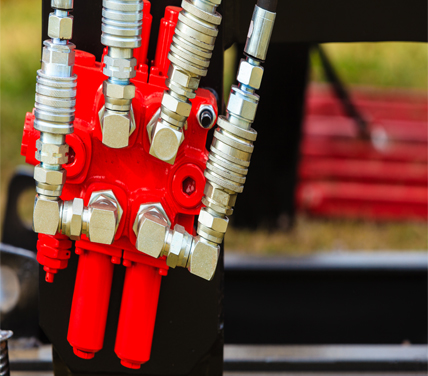

There is not much gap between low-end and mid-end products of bathroom hardware, but premium products will have higher requirements on processing technology, one-piece molding, no additional splicing, and truly meet the requirements of precision and avoid the problem of water leakage and dripping during use, and the service life is longer.

The reason for choosing a good material is that the bathroom hardware is basically placed in an environment with high humidity all year round, and it is easy to be corroded. Therefore, the bathroom hardware must choose some materials with higher corrosion resistance.

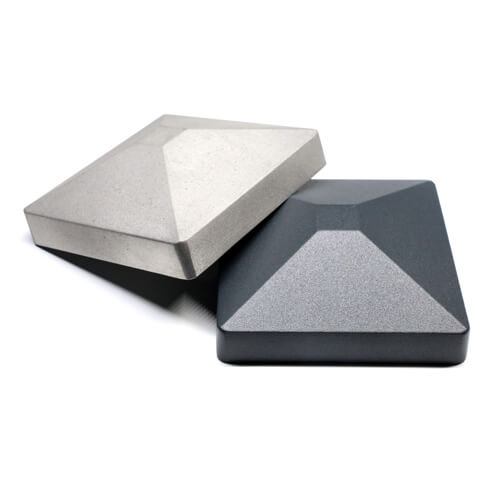

Secondly, the design of bathroom hardware is becoming more and more beautiful. For the manufacturing process, the structure is becoming more and more complex, and the surface requirements are becoming higher and higher, to achieve the purpose of improving people's life quality.

Sanitary hardware products include casting, polishing and compression molding. The materials are mainly high-quality brass, stainless steel and zinc alloy materials.

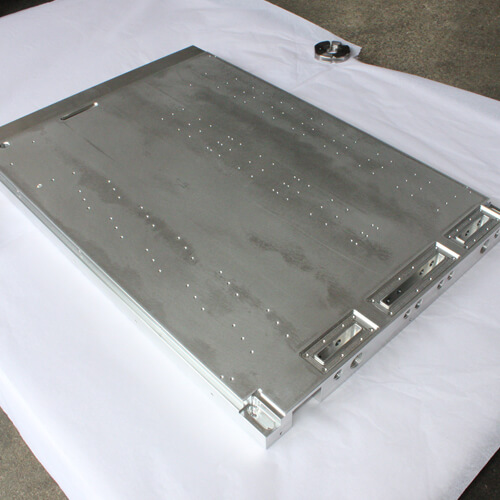

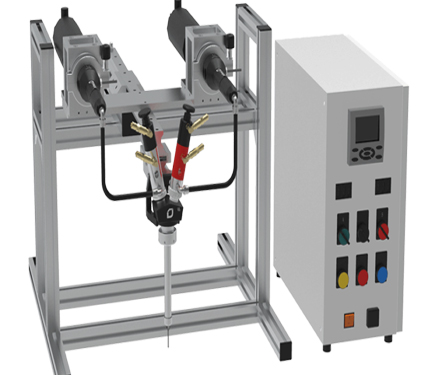

Sibai focuses on metal processing through casting blanks, CNC machining processing, CNC lathe processing, etc., and through surface treatment processes such as polishing and chrome plating, to produce the parts and meet customers’ desire.

As long as the customer provides drawings and technical requirements, Sibai will evaluate the price (such as blank material cost, cutting process cost, surface treatment cost, etc.) according to the data and processing technology , and ensure the fastest delivery time, highest quality products and services.

Welcome to Sibai.

We are looking forward to contact you!

If you have any questions or machining requests, please just leave your message here.