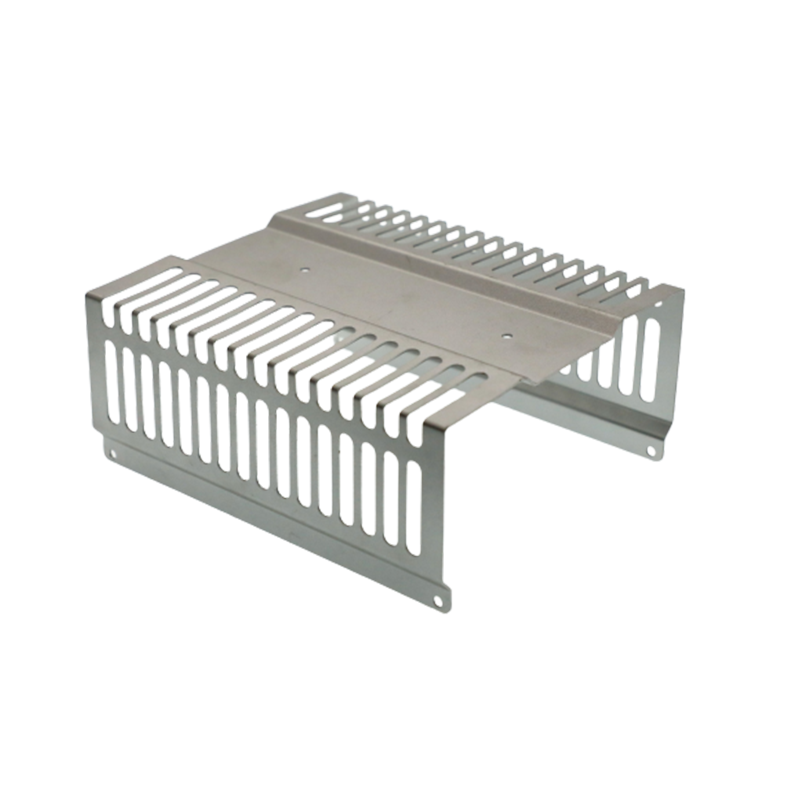

Profile Extrusion Aluminum are widely used in aluminum doors and windows, aluminum curtain walls, etc. in the construction industry.

Aluminum has good material properties, such as low density, suitable strength, good chemical stability, easy to keep clean, high electrical conductivity, good radiation properties, suitable for anodizing, and easy to process.

Aluminum can change the properties of aluminum in a wide range through additives such as magnesium (Mg), manganese (Mn), copper (Cu), silicon (Si) and some other elements, and make a variety of aluminum alloy materials with excellent properties.

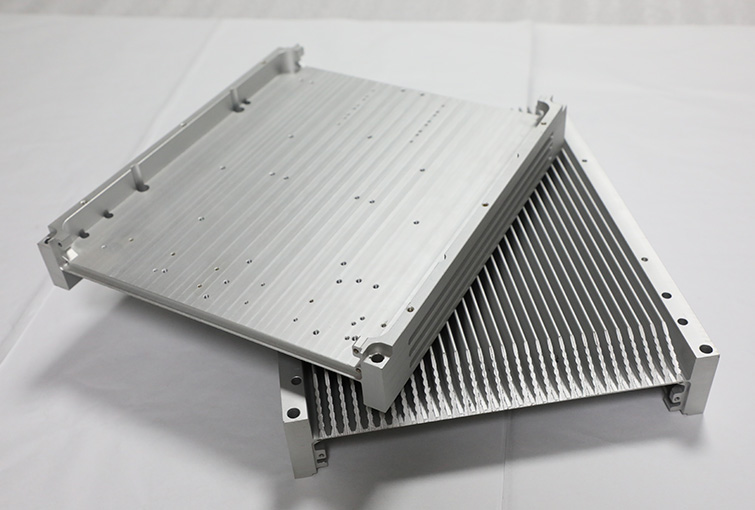

Profile Extrusion Aluminum generally require aging treatment. The aging treatment is to give the material good mechanical properties and surface quality (including pigmented surface quality). The heating temperature of the aging treatment is 560-580°C. The shortest holding time is 6 hours, and the cooling rate is 200°C/hour or more.

Profile Extrusion Aluminum generally also need surface treatment to improve the surface corrosion resistance and keep the surface glossy and not easy to scratch. At the same time, the surface of the profile has strong weathering resistance, maintains the beauty of the surface of the profile, and meets the requirements of architectural art color, so that the building has a beautiful appearance for a long time.