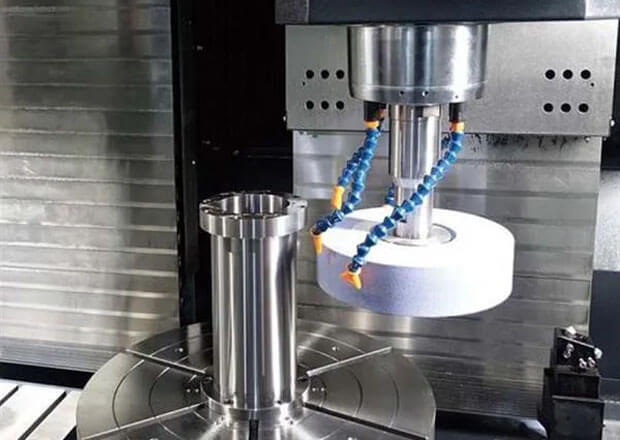

Grinding is to use grinding wheels, whetstones and abrasives (alumina, silicon carbide and other particles) to grind the surface of the workpiece.

The range of grinding processing is very wide, and almost all kinds of surfaces can be processed by grinding, such as inner and outer cylindrical surfaces, inner and outer conical surfaces, various planes, threads, gears, splines, forming surfaces, etc.

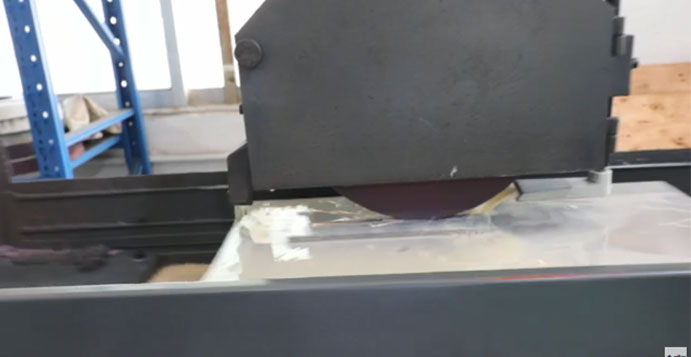

In addition, grinding can process hard materials such as hardened steel and cemented carbide that are difficult to process with general tools.

Grinding is generally used as a finishing process on the surface of a part, but it can also be used for roughing work such as pre-machining and cleaning of blanks.