EDM drilling is not limited by the hardness of metal materials, which can be used for processing super hard steel, hard alloy, copper, aluminum and any conductive material. It can use high-pressure and high-speed working fluid to quickly discharge the electric erosion material from the processing area, thereby creating favorable conditions for increasing the electric erosion speed of EDM drilling. Generally, the electrolytic erosion speed is 20-60mm/min, so the speed of EDM drilling is much higher than that of mechanical drilling. It is especially suitable for the processing of small holes of Φ0.3~Φ3mm, and the ratio of hole depth to diameter can reach 300:1.

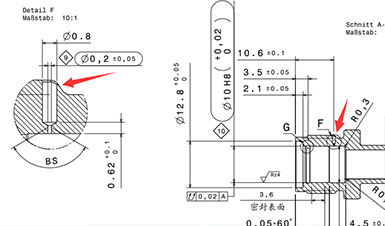

Below the drawing, we adopt EDM drilling to create Φ0.8 and Φ0.2 holes.