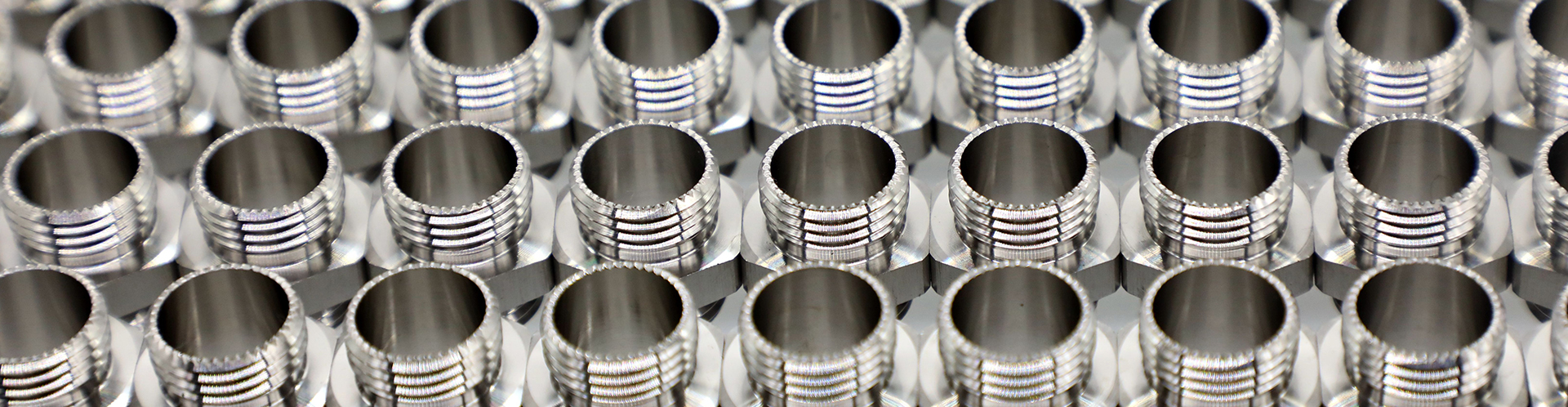

1. Sibai has suitable high tech machines for these processings.

2. Sibai has all this processing performed with the highest standards. The production follows the ISO 9001:2015 quality management system.

3. Sibai's staff is experienced in plenty types of material and can provide you with products that meet your exact specifications.

4. We have the ability to quote and customize all types of precision parts, whether simple or complex metal or plastic parts.

5. Whether customers require high precision tolerances or beautiful surface finish parts, we will never let customers down.