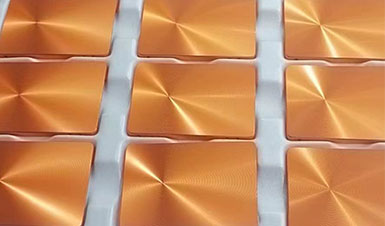

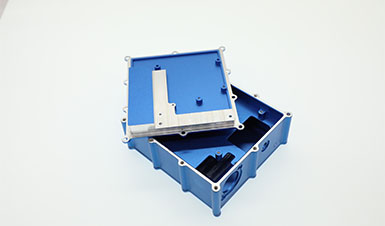

Sibai produces a large number of Aluminium CNC parts, most of which needs anodizing to be natural, black or other colors to avoid the surface scratches, or natural hurt on the surface.

What's more, some of the parts needs sandblasting before anodizing.

The sandblasting can cover the scratches of machining or handling. Some parts needs hard anodizing, for outdoor environment and for UV resistence.

Sibai collaborates with over five anodizing plants in Dongguan and Shenzhen, offering professional and experienced anodising services. We specialze in providing top-quality aluminium anodizing, ensuring superior results for all your needs.

Sibai has membrance thickness tester, which can test the thickness of the anodizing layers.