What Are The Advantages Of A 5-axis Machining Center Over 3-axis Machining Center?

A 5-axis machine ensures the best tool cutting status. It improves the cutting conditions , and it makes the cutting tool fully play its cutting performance. By a 5-axis machine, it reduces the times of clamping. It can process 5 surfaces of the workpiece in one clamping, which improves the efficiency and reduces the error caused by multiple tool setting. A 5-axis machine simplifies the technological process, improves the substantial efficiency, and can accelerate the research and development cycle of new products. It is not necessary to use long cutting tools on a 5-axis machining center, in order to avoid interference, which can increase rigidity and cutting value. And it reduces the number of cutting tools. A 5-axis machine can use not the tool tip but the tool side edges during processing. For complex processing technology, a 5-axis machine can simplify the processing process. A 5-axis machine has a higher degree of automation, which is simpler to operate than a 3-axis machine.

3+2 type 5 Axis machining center

Most of the 5-axis machines Sibai has are 3+2-type 5-axis machines, equipped with deviding head based on 3-axis machine. At present, Sibai has 8 sets of 3+2-type 5-axis machining centers. The system is from Fanuc or Mitsubishi.

What is 3+2 type machining center?

In China's machining fields, many so-called 5-axis machining centers are equipped by adding two rotating axes on the basis of 3-axis machining centers. It can achieve the effect of processing multiple faces and curved surfaces. Such a 5-axis machiningcenter is a 3+2 type machining center.

What is the difference between Chinese 3+2 machiningcenter and German 5-axis universal machine center?

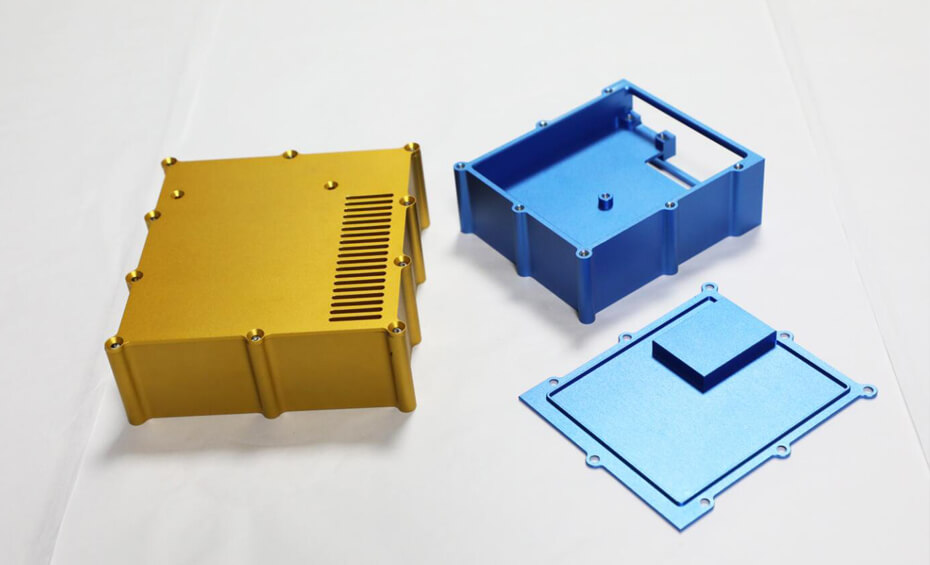

The Chinese 3+2 machiningcenter is different from the 5-axis universal machine center imported from Germany, no matter from the operating system or the effect of the universal linkage. Different from the German 5-axis universal machine , which has the RTCP (Rotated Tool Center Point), the domestic 3+2 type 5-axis machining center does not have the performance of RTCP function. Although it cannot compare with the German 5-axis universal machine, China's 3+2-type 5-axis machining center has a low price, but it can achieve high precision within a considerable precision range for most of cost-effective processed products. For majority of non-top-precision industries, China's 3+2-type 5-axis machining center can meet the needs of processing.

So what is the difference between 3-axis, 4-axis and 5-axis (3+2)?

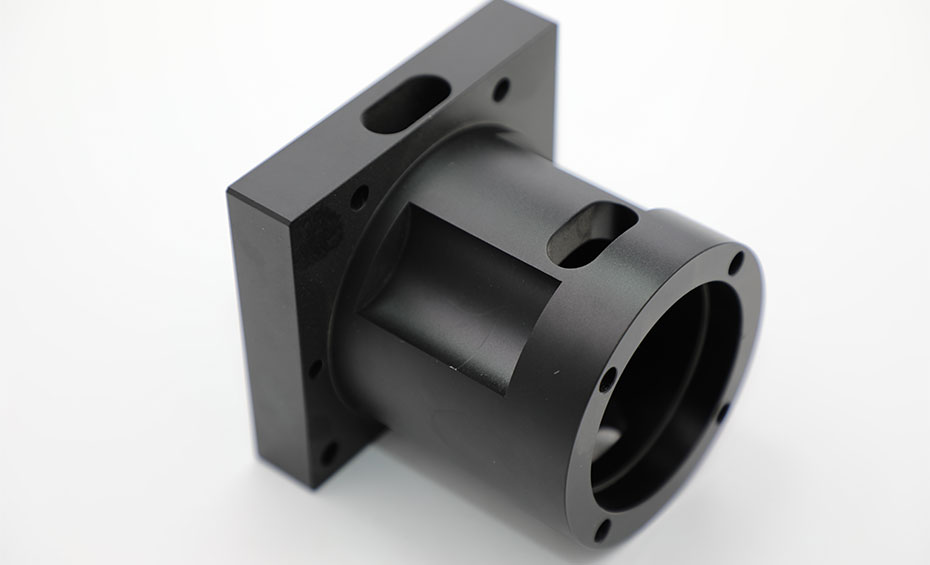

The 3-axis machining center is the most widely used at present. There are 3 axes of X, Y, and Z, that is, 3 directions of left - right, top - down, back - forth. The three-axis machining center can perform only single plane side processing.

The 4-axis machining center has one more rotary axis based on the three-axis. If the axis rotates around the X axis, it is called the A axis; and if it rotates around the Y axis, it is called the B axis. Through rotation, the product can be processed on multiple sides, which greatly improves the processing efficiency. And it reduce the times of clamping, especially the machining of cylindrical parts.

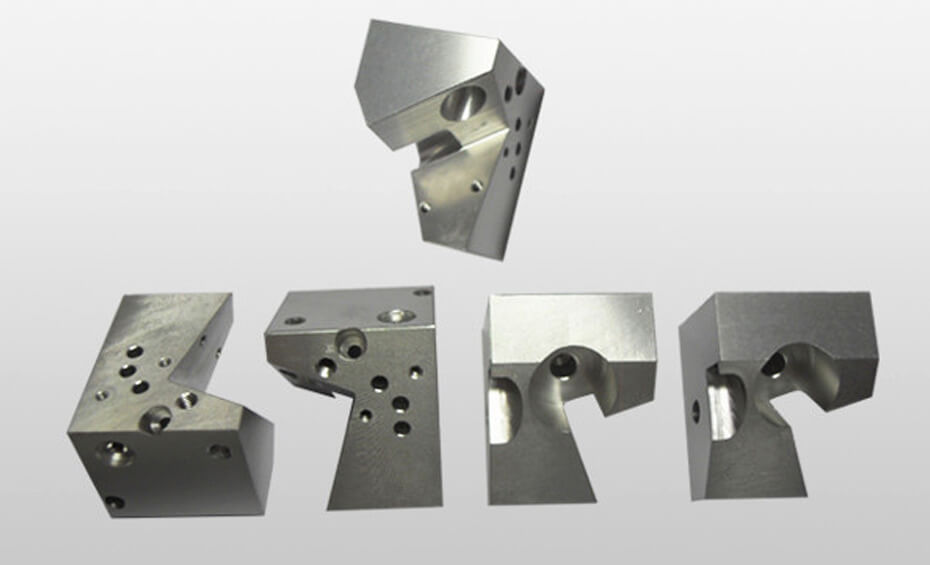

The 5-axis machining center adds 2 rotating axes on the basis of 3-axis, and can process any surfaces of the workpiece with one side fixed. That is, in addition to the 3D processing of the vertical bottom surface, it can also process side and oblique side. The 5-axis machining center is a machining center with high technology content and high precision, which is specially used for processing complex curved surfaces, complex geometry parts, with the designs of hollow, or with oblique carving or oblique holes.