In today's rapidly evolving automotive industry, precision is everything. Every component, every part, and every system needs to be flawlessly designed and manufactured to ensure optimal performance and safety on the road. This is where custom precision machining plays a crucial role. With its ability to produce intricate and specific components, custom precision machining is driving excellence in automotive systems like never before. In this blog post, we will explore the importance of custom precision machining and how it contributes to the overall success of automotive engineering.

The Basics of Custom Precision Machining

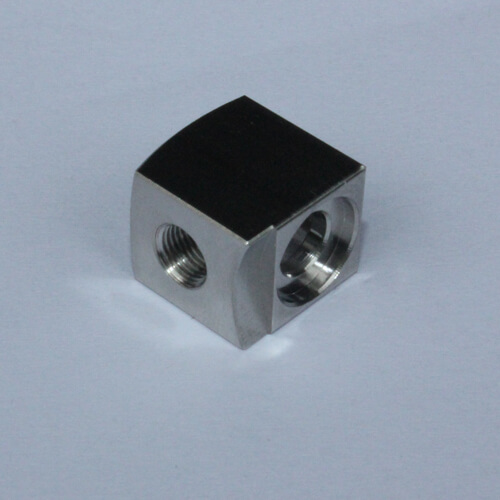

Custom precision machining is a process that involves the creation of components with extremely tight tolerances and intricate designs. It utilizes state-of-the-art machinery and cutting-edge technology to manufacture parts that perfectly fit the requirements of various automotive systems. Using computer-aided design (CAD) software and advanced machining techniques, manufacturers can create complex components with precision and accuracy that far surpasses traditional manufacturing methods.

Advancements in Automotive Systems

Over the years, automotive systems have become increasingly sophisticated, with a greater emphasis on performance, efficiency, and safety. From engine components to braking systems, every part plays a critical role in ensuring the smooth operation of vehicles. As automotive technology continues to advance, the demand for custom precision machining has skyrocketed. Manufacturers need to produce components that can withstand high temperatures, pressure, and other environmental factors while maintaining their functionality and reliability.

The Role of Custom Precision Machining in Automotive Manufacturing

Custom precision machining, like custom titanium machining, has revolutionized automotive manufacturing by providing a level of accuracy and consistency that was previously unattainable. With the ability to create complex geometries and tight tolerances, manufacturers can design and produce components that are perfectly suited to the specific needs of each automotive system. Whether it's a crucial engine part or an intricate sensor, custom precision machining ensures that every component fits seamlessly into the overall architecture of the vehicle.

SIBAI, a leading manufacturer in custom precision machining, has been at the forefront of this innovation. With their state-of-the-art facilities and highly skilled team, they have consistently delivered top-notch components that meet the stringent requirements of the automotive industry. Their expertise in custom precision machining has significantly contributed to the overall performance and reliability of countless automotive systems.

Ensuring Safety and Performance through Custom Precision Machining

Safety is paramount in the automotive industry, and custom precision machining plays a vital role in ensuring the safety of vehicles and their occupants. By manufacturing components with utmost precision, manufacturers can reduce the risk of failure and improve overall performance. Custom precision machining also enables the creation of lightweight, yet robust components, contributing to enhanced fuel efficiency and reduced emissions.

In conclusion, custom precision machining is a critical element in driving excellence in automotive systems. Its ability to produce intricate and specific components with unparalleled precision and accuracy has transformed the industry. As automotive technology continues to evolve, custom precision machining will remain an invaluable tool in the pursuit of safer, more efficient, and high-performing vehicles.