Dispensing technology plays a crucial role in various industries, ensuring accurate and controlled delivery of fluids and materials. From pharmaceuticals and food production to electronics and automotive manufacturing, precision in dispensing technology is paramount for consistent quality and efficiency. One of the key advancements in this field is the application of CNC machining technology, which enables enhanced precision and reliability in fluidic systems. In this blog post, we will explore how CNC machining is transforming dispensing technology, revolutionizing industries and delivering superior results.

The Role of CNC Machining in Dispensing Technology

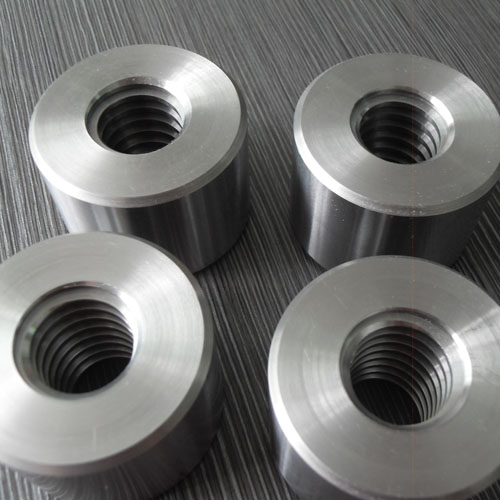

CNC machining technology stands at the forefront of precision engineering, offering unparalleled control over complex manufacturing processes. In the realm of dispensing technology, CNC machining plays a pivotal role in the fabrication of components such as valves, nozzles, and pumps. By employing computer-controlled cutting and shaping techniques, CNC machining ensures the creation of intricate geometries with utmost precision. This level of accuracy is vital for designing dispensing systems that can handle a wide range of materials, viscosities, and flow rates efficiently.

Precision at its Finest: How CNC Machining Enhances Accuracy

The key advantage of CNC machining lies in its ability to consistently replicate intricate designs with exceptional accuracy. This feature is especially critical for dispensing systems, where even slight deviations can result in dosing errors and product inconsistencies. CNC-machined components exhibit minimal tolerances, ensuring precise and repeatable flow control over extended periods. The elimination of human error and the ability to execute complex machining operations guarantees unmatched precision, bolstering the performance and reliability of dispensing technology.

Customization and Flexibility with CNC Machining in Dispensing Systems

Fluidic applications often require customized solutions to meet specific requirements. CNC machining empowers dispensing technology with unparalleled flexibility, enabling the production of tailor-made components. Manufacturers can easily modify designs, adapt to changing demands, and experiment with different materials without compromising accuracy or performance. Whether it's intricate microfluidic channels or specialized dispensing nozzles, CNC machining technology provides the agility and versatility necessary in the rapidly evolving landscape of modern dispensing systems.

Future Directions: Advancements in CNC Machining Technology for Dispensing Applications

As technology continues to advance, so does the field of CNC machining. In the context of dispensing technology, ongoing research and development efforts aim to further enhance precision and efficiency. Innovations such as multi-axis machining and additive manufacturing techniques are pushing the boundaries of design possibilities, allowing for even more intricate and complex fluidic systems. Simultaneously, advancements in CNC programming and automation are streamlining manufacturing processes, reducing production time, and optimizing overall productivity.

In conclusion, CNC machining technology is revolutionizing dispensing technology by enabling unmatched precision, accuracy, customization, and flexibility. With its ability to manufacture intricate components and consistently replicate designs with minimal tolerances, CNC machining plays a critical role in enhancing the performance and reliability of fluidic systems. As advancements in CNC machining continue to unfold, the future of dispensing technology promises even greater levels of precision and efficiency, catering to the evolving demands of various industries.