In the ever-evolving world of technology, drones have emerged as a versatile tool that is revolutionizing various sectors, including photography, videography, agriculture, and even deliveries. These unmanned aerial vehicles (UAVs) are becoming increasingly popular due to their ability to access remote areas, collect data, and perform tasks with utmost accuracy and efficiency. One crucial factor that directly impacts the performance of drones is the quality and precision of their components. One particularly valuable component is aluminum casting parts.

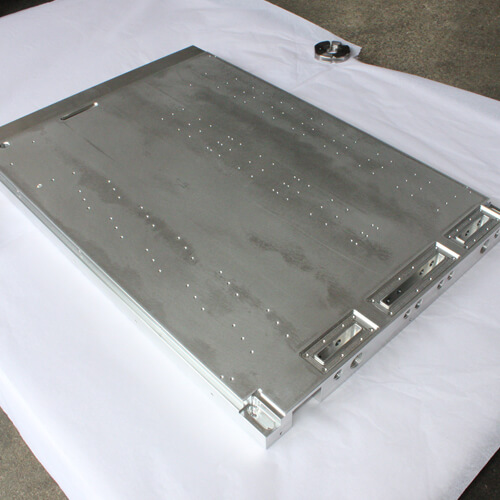

SIBAI, a renowned brand in the aerospace industry, specializes in the production of precision aluminum casting parts. With their expertise and state-of-the-art manufacturing processes, SIBAI ensures that drones achieve optimal performance with their high-quality aluminum casting parts.

The use of aluminum in drone manufacturing is no coincidence. Aluminum offers a perfect combination of strength, lightness, and durability, making it an ideal material for constructing drone frames, arms, and other components. By utilizing aluminum casting parts, SIBAI guarantees the accurate reproduction of intricate designs and shapes, resulting in precise and efficient drone performance.

Enhanced Durability and Performance

One of the primary advantages of using aluminum casting parts in drone production is the enhanced durability and performance they offer. Aluminum's exceptional strength-to-weight ratio allows for robust structures that can withstand impact and vibrations while remaining lightweight. This durability ensures that drones can handle demanding conditions and perform optimally for extended periods.

Weight Reduction for Increased Efficiency

Weight reduction is a critical factor in drone design, as it directly affects flight efficiency and endurance. Aluminum casting parts allow manufacturers to design and produce lightweight drone components without sacrificing structural integrity. By incorporating lightweight aluminum casting parts, drones can carry heavier payloads, fly for longer durations, and achieve higher speeds.

Complex Designs for Precision Maneuvers

The flexibility and versatility of aluminum casting enable the production of complex designs and intricate shapes that are difficult to achieve with traditional manufacturing techniques. These intricate designs allow drones to perform precise maneuvers, making them especially useful for tasks such as aerial inspections, mapping, and surveillance. With SIBAI's expertise in aluminum casting, drones can execute intricate flight patterns with accuracy and reliability.

Resistance to Corrosion and Extreme Temperatures

Drones often encounter harsh environmental conditions, including extreme temperatures, humidity, and corrosive elements. Aluminum has excellent corrosion resistance and demonstrates stable mechanical properties across a wide range of temperatures. By utilizing aluminum casting parts, drones are equipped to withstand these challenging conditions without compromising performance, longevity, or safety.

In summary, the use of aluminum casting parts significantly elevates the performance of drones. SIBAI, a leading brand in the aerospace industry, specializes in precision manufacturing of aluminum casting parts, ensuring the durability, lightweight construction, precision maneuverability, and resistance to harsh environmental conditions required for drones to excel. As the demand for drones continues to rise, the partnership between SIBAI and the drone industry will undoubtedly contribute to the advancement and evolution of this groundbreaking technology.